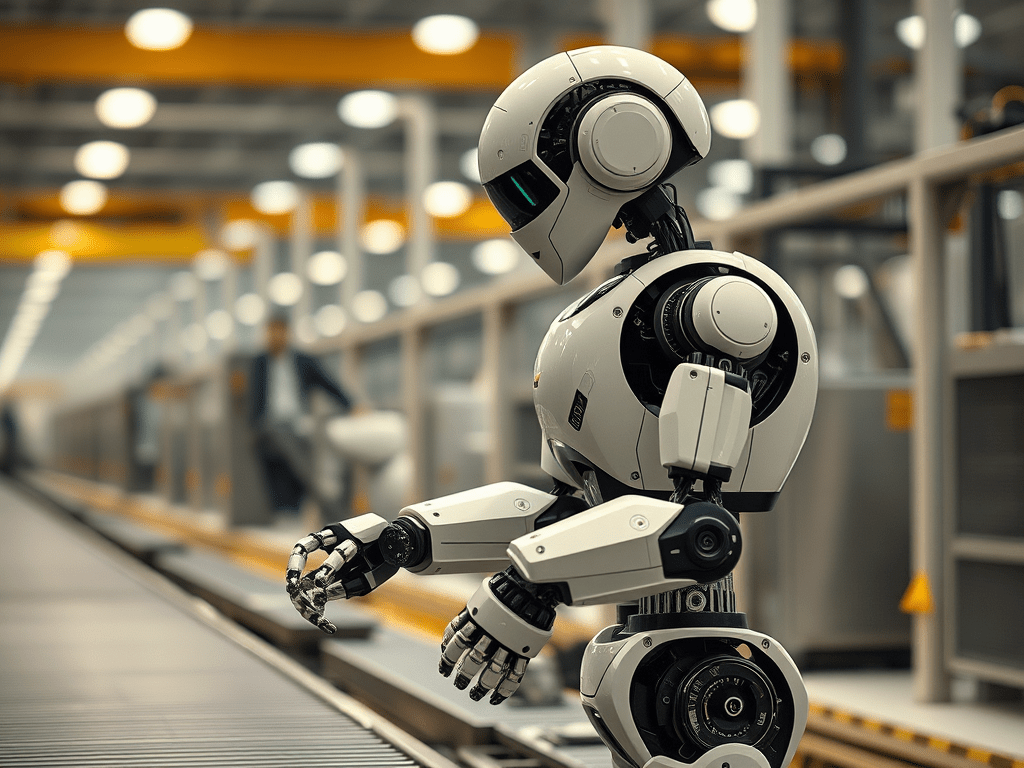

Humanoid robots, a type of robot designed to mimic human physical and cognitive functions, are rapidly advancing with technological developments in artificial intelligence, mechanics, and materials science. These robots are distinguished by their anthropomorphic structure, typically resembling the human form with two arms, legs, and a head, enabling them to perform tasks in environments built for human workers. While robots in various forms have been employed in manufacturing for decades, the emergence of humanoid robots marks a potential paradigm shift. The applications of humanoid robots in manufacturing are poised to bring about sweeping changes in productivity, labor dynamics, and the global economy.

The Rise of Humanoid Robots in Manufacturing

Technological Advancements Driving Humanoid Robots

The evolution of humanoid robots has been enabled by breakthroughs across several fields:

- Artificial Intelligence (AI): AI enables humanoid robots to perform complex tasks autonomously, learning from their environment, adapting to new situations, and optimizing their actions over time. Machine learning algorithms, particularly deep learning, allow robots to recognize patterns, predict outcomes, and make decisions based on accumulated data.

- Sensors and Vision Systems: Advanced sensors, such as LiDAR, ultrasonic, and camera-based systems, enable robots to interpret their surroundings with precision. This capability is essential for tasks such as object recognition, navigation, and assessing the quality of their work. Visual sensors integrated with AI models further allow humanoid robots to “see” and interact with the world.

- Mechanical Design and Materials: Humanoid robots require an intricate balance of flexibility and durability in their materials and mechanical structure. With lighter, stronger materials and innovations in hydraulic and electric actuators, robots can now perform actions that were previously impossible, such as lifting heavy objects with precision or handling delicate items without causing damage.

Applications of Humanoid Robots in Manufacturing

Humanoid robots can perform a wide array of tasks within manufacturing environments:

- Assembly Line Operations: Humanoid robots can work alongside human employees on assembly lines, performing repetitive tasks like screwing bolts, attaching components, and packaging. Unlike traditional robots, they are adaptable and can be reprogrammed to perform different tasks without extensive reconfiguration of the assembly line.

- Quality Control: Vision systems and AI enable humanoid robots to conduct quality inspections, identifying defects or irregularities in manufactured products with high precision. By detecting flaws early, robots can help improve the overall quality of goods and reduce waste.

- Maintenance and Repair: Some humanoid robots are being developed to maintain and repair machinery. Equipped with diagnostic tools and sensors, these robots can monitor machine health, perform repairs, and even replace worn-out parts autonomously, minimizing downtime in manufacturing operations.

- Inventory Management: Humanoid robots can assist with tracking inventory levels, moving items within warehouses, and preparing shipments. They can operate in spaces designed for human workers, reducing the need for specialized robotic equipment.

Advantages Over Traditional Industrial Robots

While traditional robots are widely used in manufacturing, they are often limited to performing specific, repetitive tasks in controlled environments. Humanoid robots, however, have several unique advantages:

- Adaptability: Humanoid robots can be programmed for various tasks without the need for extensive retooling, making them more versatile in dynamic production environments.

- Human-Robot Collaboration: Humanoid robots are designed to work alongside human employees, rather than replacing them. This collaboration can create a safer, more efficient, and productive workplace where robots handle labor-intensive tasks, and humans focus on more complex or creative responsibilities.

- Ease of Integration: Because humanoid robots resemble human workers in form and function, they can operate in existing manufacturing facilities without requiring major modifications to the workspace, reducing costs and logistical challenges.

Economic Impacts of Humanoid Robots in Manufacturing

The integration of humanoid robots into manufacturing is expected to bring about significant changes to the economy. These impacts can be analyzed on both macro and microeconomic levels, touching upon productivity, labor dynamics, and global trade.

Increased Productivity and Efficiency

Humanoid robots can operate continuously without the need for rest, thereby improving productivity. In manufacturing, this round-the-clock operation leads to a significant increase in output and cost savings. Furthermore, humanoid robots can maintain consistent levels of precision, reducing error rates and minimizing rework costs. The enhanced efficiency translates into lower production costs, allowing companies to offer more competitive prices and increase their profitability.

Labor Market Disruption and Job Transformation

One of the most debated consequences of humanoid robots is their impact on the labor market. The automation of certain tasks will inevitably reduce the demand for specific types of labor in manufacturing. However, the adoption of humanoid robots may also lead to job transformation rather than mere displacement.

- Shift from Manual Labor to Skilled Roles: As robots handle repetitive tasks, there will be an increased demand for skilled workers capable of programming, maintaining, and optimizing robotic systems. This shift may lead to the creation of new jobs in robotics, AI, and data analysis.

- Job Creation in Robotics and AI Development: The development, production, and maintenance of humanoid robots require expertise in fields such as robotics engineering, machine learning, and hardware design. Companies focusing on these areas are likely to see job growth as the demand for humanoid robots increases.

- Reskilling and Workforce Adaptation: As certain roles become obsolete, reskilling programs will become essential to help workers transition into new roles that involve working alongside robots or managing automated systems. This need for reskilling may drive governments, educational institutions, and companies to invest in workforce development programs.

Influence on Global Trade and Manufacturing Locations

Humanoid robots are likely to influence global trade patterns by shifting manufacturing decisions. Traditionally, companies have outsourced production to regions with low labor costs. However, as humanoid robots become cost-effective and capable of performing tasks previously done by human workers, companies may increasingly opt for “reshoring” — bringing manufacturing back to their home countries.

This shift could have significant geopolitical implications, as the reliance on low-cost labor markets decreases. Manufacturing companies in high-cost countries may gain a competitive advantage by using humanoid robots to reduce labor costs and increase production capacity. Countries traditionally dependent on low-wage manufacturing may need to explore alternative economic models, focusing on innovation, design, and value-added services.

Impact on Supply Chains and Inventory Management

The ability of humanoid robots to manage inventory and fulfill orders autonomously could revolutionize supply chains. By optimizing production and distribution processes, robots can help minimize inventory costs and reduce the time required to move products from the factory floor to the consumer. Furthermore, real-time data collection and analysis by humanoid robots can improve demand forecasting, reducing the risks of overproduction or stockouts.

Broader Economic Implications of Humanoid Robots

Economic Growth and New Markets

The market for humanoid robots in manufacturing is expected to grow rapidly, creating opportunities for startups and established tech companies alike. Robotics companies specializing in humanoid designs will see increased demand, driving economic growth in the technology and manufacturing sectors. As robots become more capable, industries beyond manufacturing, such as healthcare, logistics, and retail, may adopt humanoid robots, further expanding the market.

Changes in International Economic Balance

Humanoid robots may alter the balance of economic power between nations. Countries that excel in robotics and AI, such as Japan, South Korea, and the United States, could experience significant economic growth as they export these technologies globally. Developing countries with economies heavily reliant on labor-intensive manufacturing may face challenges if demand for low-cost human labor decreases, potentially leading to economic restructuring.

Societal Impacts and the Future of Work

The widespread adoption of humanoid robots will bring about important societal changes. As traditional manufacturing jobs evolve or become obsolete, there will be an increased need for social policies to address potential unemployment and income inequality. Governments may need to explore universal basic income (UBI), tax incentives for companies that invest in reskilling programs, and initiatives to promote technology literacy.

Additionally, the shift in job roles may lead to new opportunities for creativity, innovation, and human-centric work. With robots taking over repetitive tasks, humans may focus more on roles that require problem-solving, emotional intelligence, and interpersonal skills, which are difficult to replicate with current technology.

Summary

Humanoid robots are poised to transform the manufacturing sector and the broader global economy. By increasing productivity, reducing costs, and enhancing operational flexibility, they present an attractive solution for companies seeking to stay competitive in an increasingly automated world. The adoption of humanoid robots, however, will also necessitate significant adjustments in labor markets, education systems, and international trade. While the potential for economic growth is substantial, careful management of the transition will be important to address the social and economic challenges that may arise.

The ongoing evolution of humanoid robots represents both an opportunity and a challenge for humanity. Their successful integration into manufacturing could mark the beginning of a new era in which human workers and humanoid robots coexist and collaborate, unlocking new possibilities for economic and social development.